Why you should consider replacing your existing step-up and step-down transformers with Amorphous Core transformers

Transformers are employed widely and for a multitude of purposes. Due to their long history, they have become overlooked and regarded as a constant, something that does a job and only requires attention if a problem occurs. However, now more than ever, businesses need to look at their site’s energy use holistically in order to achieve the UK’s ambitious Net-Zero targets.

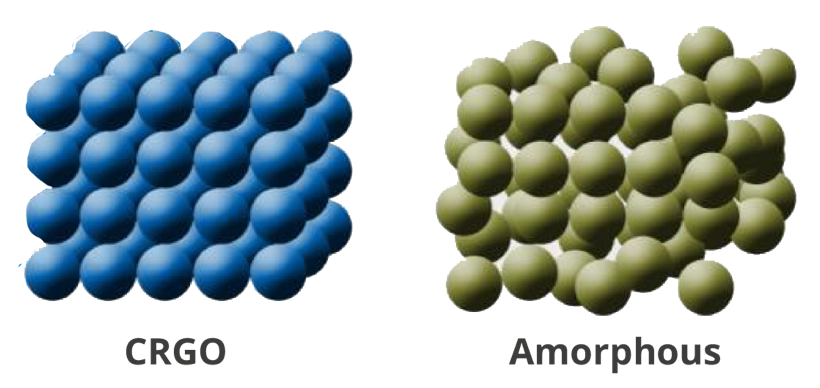

Amorphous Core technology has been widely researched and findings show that Amorphous Core transformers provide a super-low core loss alternative to conventional cold rolled grain orientated steel (CRGO) transformers. This newer technology provides higher efficiencies, longevity and low magnetising current.

Due to the atomic structure and thickness of the Amorphous Core metal material, up to 80% of the losses experienced by conventional transformers are avoided. It is the random pattern of the amorphous atom that allows for lower resistance to magnetisation cycles and delivers lower core losses.

This high level of efficiency delivers substantial savings in operating costs and thousands of kg of savings in CO2 annually.

But Aren’t Amorphous Core Transformers More Expensive?

Whilst conventional transformers are initially cheaper than Amorphous Core transformers, they consume their initial purchase cost in wasted energy approximately every 9 months (based on the industry standard of 5% losses). Therefore, over a period of 15 years, traditional transformers will consume 20 times their purchase price in energy losses and emit in excess of 73,000kg of CO2. In contrast each of Powerstar’s Amorphous Core transformers will only consume between £200 and £300 of energy per year as their losses are less than 1%, taking more than 20 years to consume their initial cost in energy, and saving more than 78,000kg CO2 in this period.

Benefits

- Up to 80% lower core losses compared to CRGO transformers

- Delivers greater consumption savings on average compared to traditional CRGO transformers

- Contributes towards CS by reducing CO2 emissions

- Gain instant energy consumption savings

- Reduce operating costs

Amorphous core transformers can be retrofitted to all new and used machine tools.

See how much money and energy you could save by switching to an amorphous core transformer

https://hyfore.com/green-initiatives/