CNC Rotary tables, 4th and 5th axis – Rob Beckett, Workholding Product Manager at Hyfore, looks at some of the reasons fueling an increase in popularity.

Machine shops are increasingly being constrained for space, and companies are looking to get even more out of their current machines when looking to meet customer demand for quicker lead times and more complex components.

Cue rotary tables.

With floor space at a premium and Brexit causing some investment decisions to be put on hold, we have seen a major increase in the number of enquiries for 4th and 5th axis rotary tables at Hyfore.

These are coming from customers involved in the automotive, aerospace, medical and packaging sectors, where high precision parts are increasingly the norm and more small batch orders are proving common.

Cost-saving:

This would normally come from machinists who have a 3-axis machine but are looking for greater flexibility. Alleviating the need to spend a considerable amount of money on a 5-axis machine. For example, the software, motors, cables and rotary table could cost between £25k and £30k, compared to a new machine starting from £140,000.

It may just be an initial order or a speculative project, so being able to cost-effectively test the market or deliver on a specific component is worth its weight in gold. Manufacturers temper their desire for growth by ensuring they don’t financially overstretch themselves.

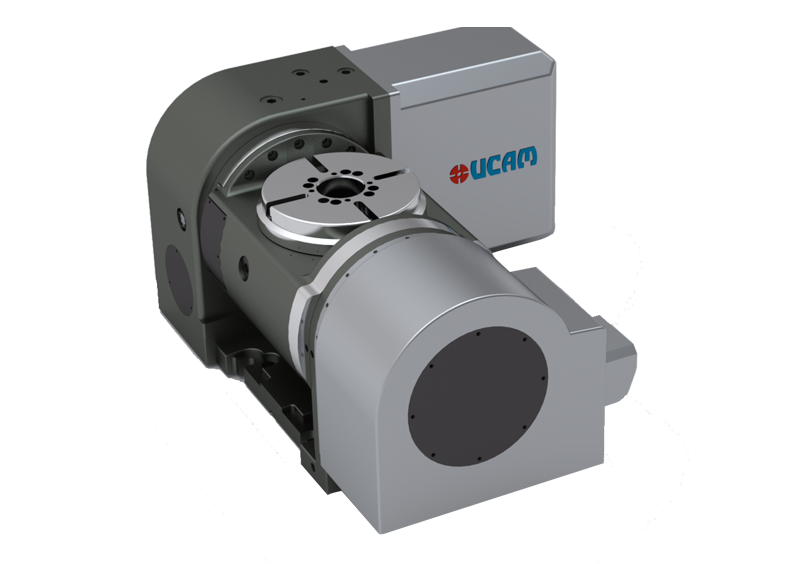

Hyfore’s strategic partnership with UCAM has seen us become an exclusive UK distributor for their precision CNC Rotary Tables. It is known for its quality, reliability and performance, with its tilting capability allowing components to move 360 degrees so that the cutting tool can machine on all five sides. Thus, reducing secondary and third operations in the process.

Short lead-times:

We are currently working on eight live enquiries and our approach is to go into a manufacturer and look at their specific project, what they are machining and what future capacity they may need.

This gives us the insight we require to suggest a number of solutions and, once the package is agreed, we can deliver the 4th or 5th axis rotary table within four weeks.

These can be fitted by the customer or through our own internal installers and network of sub-contractors.

Rotary tables are an interesting ingredient in the current machine shop debate. They’re not right for every application, but they can certainly add an extra dimension to your capabilities at a relatively low cost.

Our CNC Rotary Tables

CNC Rotary Indexers

Rotary indexers help move and position your workpieces during manufacturing, allowing for precise alignment and accurate repeatability when moving parts mid-process. Precision on the move.

These indexers rotate your workpieces to a predetermined location, which can be constant or changeable.

Unlike a rotary table, which can rotate constantly, an indexer locks itself in place when it reaches a desired position before machining begins.

Rotary indexers work similarly to a circular assembly line, positioning your items precisely around a workspace so you can work on them as necessary.

E-Series

The limit values as set out in the corresponding parameter list take precedence over the data and information provided in the main catalog (due to motor, drive enhancement and the respective machine CNC)

Motor-dependent data are optimum values at operating temperature

Find out more

5C2 Rotary Indexer Single

The 5C2 Rotary System is based on a long history of Hardinge 5C spindle and manual indexer designs. Over 60 years of Hardinge-engineered and proven mechanical elements guarantee an accurate, repeatable, reliable and flexible product.

Find out more

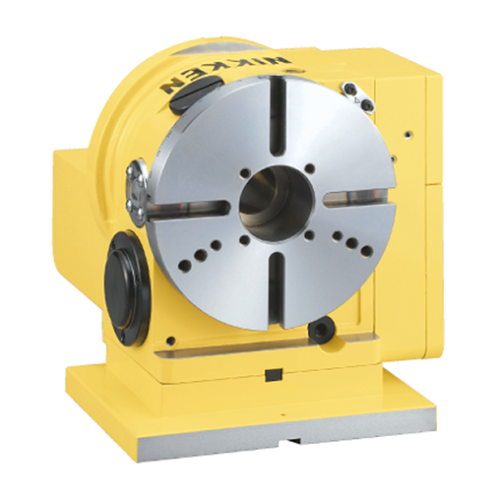

4th Axis Rotary Table

A 4th Axis Rotary table can rotate a workpiece or cutting tool around a fourth axis (typically called the A-axis.)

This additional rotational axis allows for more complex and multi-sided machining operations, perfect for milling, cutting, drilling and more.

In a 4th Axis Rotary Table, the workpiece or tool is securely mounted on the table, and the table itself can rotate, giving you precise control over the angular positioning of the workpiece.

This feature enables the machine to perform operations that involve intricate angles and contours. It’s commonly used for creating undercuts, angled holes, and complex shapes requiring multi-sided machining.

Adding a 4th Axis Rotary Table increases the versatility and efficiency of your setup. It also enhances the precision of your machining processes – mainly when producing more intricate parts – as you can incrementally change the workpiece’s position without resetting the workholding.

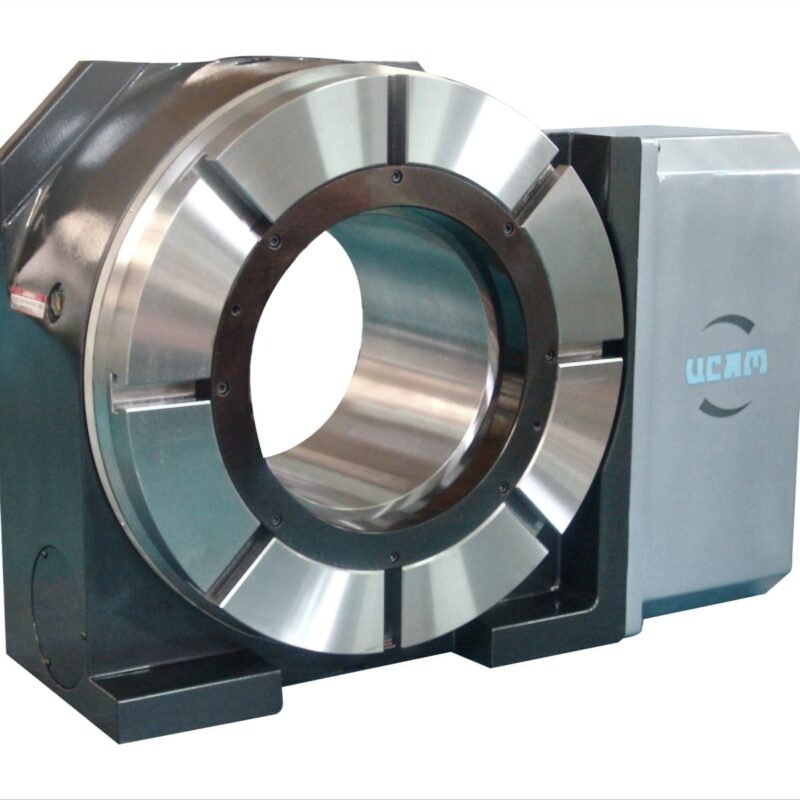

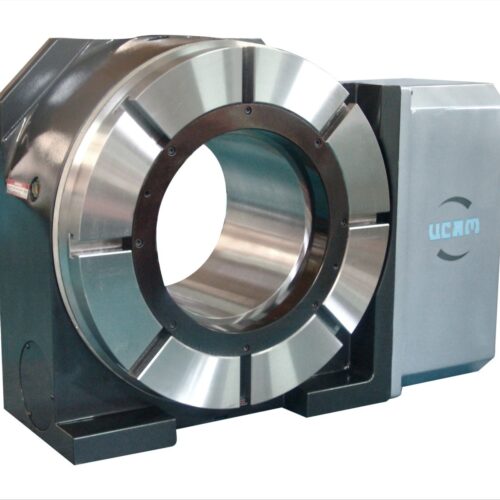

Large Bore Rotary Table ULBR-800

- Hydraulic Clamping

- High Grade C I Construction

- Dual Lead Worm Gear Set

- Motor mounting & Drive elements to suit motor

- Vertical mounting

- Option available with Vertical / Horizontal mounting

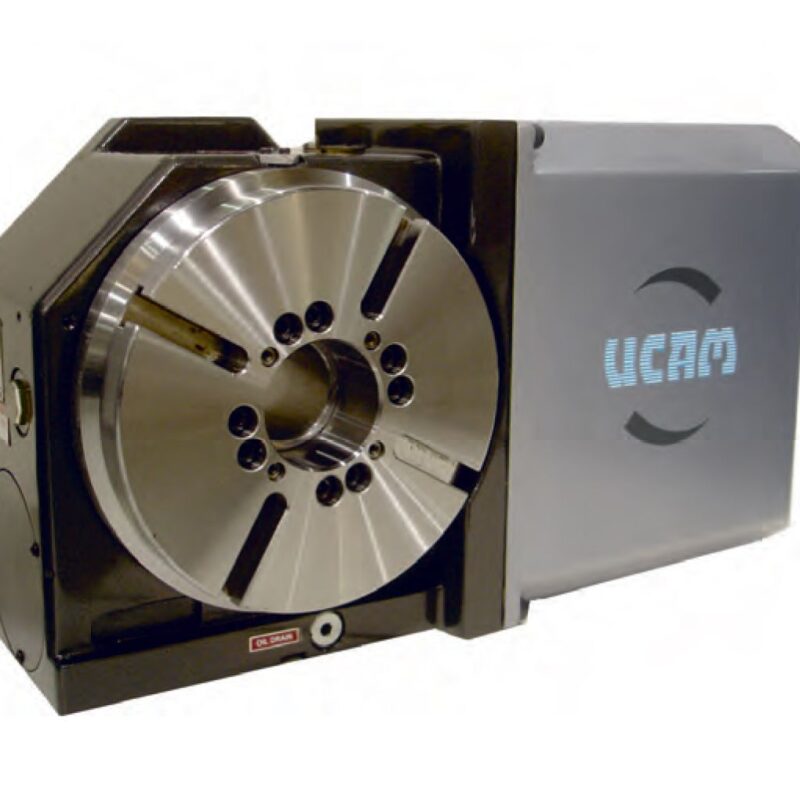

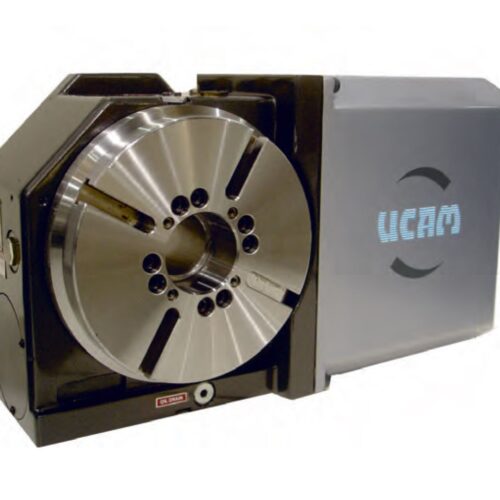

CNC Rotary Table URH-631

- Pneumatic / Hydraulic Clamping

- Pre-Loaded Axial Radial Roller Bearer

- Gear Mechanism – Motor to Worm Shaft

- Dual Lead Worm Gear set

- Vertical mounting

- Option available with vertical / Horizontal mounting

Back Side Motor Mounted CNC Rotary Table – CNC202B

- Wide application can be offered from small Drilling Press to M/C.

- Suitable for indexing/leads cutting of small size work pieces.

- Various kinds of the work chucking attachments can be offered from 5C collet fixtures to air/hyd. chuck

5th Axis Rotary Table

A 5th Axis Rotary Table provides even more freedom for workpiece positioning and tool orientation, further enhancing the machining capabilities of your setup.

Used in conjunction with the standard X, Y, and Z linear axes and a rotary A-axis or B-axis, the 5th axis provides rotation around either the A-axis or a B-axis, allowing the machine to tilt or swivel the workpiece or cutting tool during production.

This added rotational capability enables the machine to approach the workpiece from various angles and orientations, allowing for more complex machining operations and detailed components.

Using a 5th Axis Rotary Table increases machining precision, accuracy, speed and versatility.

It also facilitates a better-quality finish for the final product.

For these reasons, 5th Axis Rotary Tables are commonly used in aerospace, automotive, and medical device manufacturing industries for producing intricate parts.

They are a valuable tool for achieving high precision and efficiency in many complex and demanding CNC machining operations.

CNC Tilting Rotary Table USSR-201

- Pre-loaded axial radial roller bearer

- Diameter of table: Ø 200 (mm)

- Total reduction ratio: 1:90

- Rotation speed: 33.3 (rpm)

- Maximum work load on the table – horizontal: 100 (kg)

- Maximum work load on the table – vertical: 65 (kg)

- Driving torque: 250 (Nm)

- Indexing accuracy: ±15″ / ±30″ (rotary axis/tilting axis)

- Net weight: 200 (kg)

Compact Tilting Rotary Table – 5AX-4MT-120

- Tilting rotary table with Multi-Spindle

- Various attachment for fixing work piece

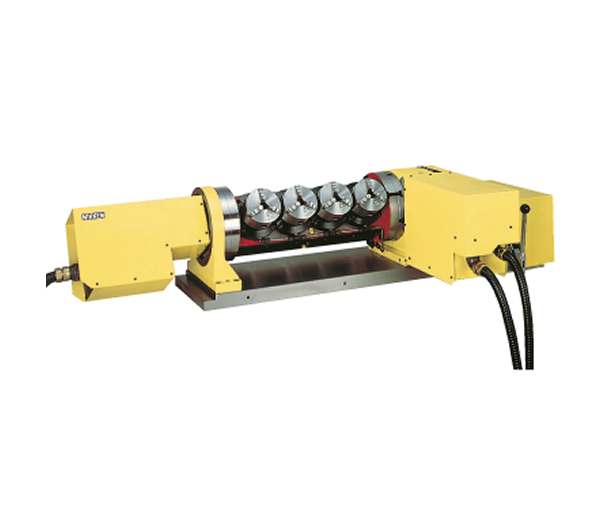

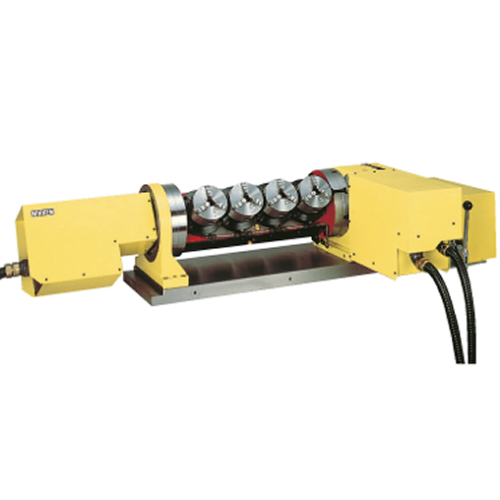

Multi Spindle Rotary Table

A Multi-Spindle Rotary Table combines the rotational features of a rotary table with multiple spindles, which are powered by a single motor.

These spindles are responsible for holding and driving cutting tools or workpieces, allowing you to simultaneously machine or process several workpieces.

As the table rotates or indexes, each spindle can perform various operations on the different workpieces.

You can customise the pitch of the spindles and tilt of the table to suit your requirements.

Multi-spindle machines are commonly used in various high-precision industries, including aerospace, automotive, and medical sectors, where accuracy and high production rates are essential.

They are valuable tools for drilling, milling, grinding, and other machining operations that require precise positioning.

Direct Drive Rotary Table

Direct Drive Rotary Tables feature an integrated motor system that directly powers the rotary table’s motion along its axes and faceplate.

This built-in power eliminates the need for additional mechanical components like gears or belts. It enables the machine to achieve exceptionally rapid rotational speeds, swift acceleration and deceleration in line with the motor’s torque capacity.

The integrated motor also controls the table’s movement, enabling complex and synchronised machining operations.

The absence of mechanical components reduces backlash and mechanical losses, improving accuracy and repeatability.

Direct Drive Rotary Tables are commonly used in semiconductor manufacturing, aerospace, medical device production, and any application that demands accurate positioning and rapid movements.

Benefits of CNC Rotary Tables

Customisation and adaptability:

Rotary tables can be adapted to various machining setups and applications. This adaptability makes them suitable for a wide range of industries and manufacturing processes.

Integration with CNC Systems:

Many rotary tables can be integrated with CNC (Computer Numerical Control) systems, allowing for automated and programmable machining processes. This enhances precision and repeatability.

Reduced Human Error:

Automation through rotary tables reduces the reliance on manual positioning and handling, minimizing the risk of human error in the machining process.

Understanding these benefits helps manufacturers and machinists make informed decisions about incorporating rotary tables into their operations, considering the specific needs and goals of their projects.

Versatility:

Rotary tables are versatile tools that can be used for a variety of machining operations, including milling, drilling, boring, and indexing. Their ability to rotate workpieces allows for complex and multi-sided machining.

Increased Productivity:

With a rotary table, multiple machining operations can be performed without the need to reposition or reset the workpiece. This reduces downtime and increases overall productivity.

Precision and Accuracy:

Rotary tables are designed for high precision and accuracy. They enable precise positioning and machining of workpieces, ensuring that the desired specifications are met.

Complex Geometry:

Machining complex shapes and features becomes easier with a rotary table. It allows for the machining of intricate geometries and contours that may be challenging with traditional machining methods.

Efficient Batch Production:

For batch production of parts with similar features, a rotary table can streamline the process. Once the initial setup is done, it’s easy to replicate the same machining operations on multiple workpieces.

Increased Tool Life:

The ability to rotate the workpiece during machining can lead to more efficient tool usage. Tools wear more evenly, and cutting forces are distributed, potentially extending tool life.

Have a look at the products we have on offer at hyfore.shop/rotary-tables

Specific products can be located below: