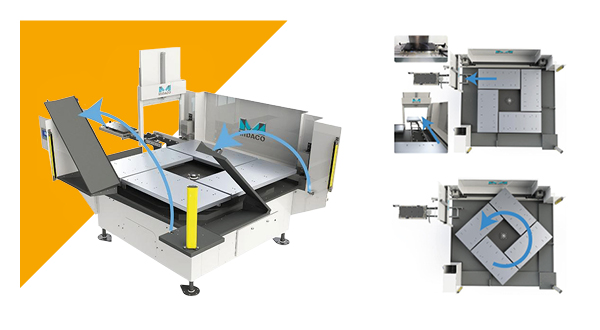

One, shuttle, one receiver, FOUR Pallets

– scheduled and ready to feed your VMC for multiple hours of unattended machining.

Whether running high-volume production of the same part or programming several different set-ups, the Automatic Rotary 4 Station Pallet Changer will increase operator walk-away time and maximize productivity on your new or existing vertical mill. Save money with less spindle idle time due to part change-over and quote your customers more competitively.

Reduce your machine’s idle time

Change parts OUTSIDE the VMC while it’s cutting and keep the chips flying. Learn how adding a MIDACO pallet changer to your new or existing Vertical Machining Centre will dramatically reduce your machine’s idle time.

More MIDACO systems

Midaco’s Automatic and Manual Pallet Changer Systems, Automatic Door Systems and Trunnion Systems improve efficiency in all aspects of manufacturing including new and existing, large or small VMCs, Bridge Mill, HMC, Drill/Tap and EDM machines.

Take the challenge!

Get a glimpse of what you will be able to save by upgrading your company’s efficiency with a MIDACO Pallet Changer using our cost-saving Payback Calculator.