CNC collets are a key member of the modern workholding family. They’re used across a wide range of industries and crafts, providing the ideal solution to various clamping requirements.

In this blog article, we’ll dive into the subject of collets and examine their uses, pros, and cons. Furthermore, we’ll break down the different types of collets available for the metalworking industry in particular.

Discover how collets can enhance your workholding processes with exceptional precision.

Which type of collets can Hyfore offer?

At Hyfore Workholding, we supply a leading range of collet options. While the options available are primarily for the metalworking industry, the applications of collets, as listed here, are far-reaching.

We supply the following collet workholding:

1. C-style collets

C-style collets are cylindrical workholding devices used to clamp machine spindles for accurate, high-speed rotary machining. The spindle is inserted into the collet, and the collet is tightened using a nut, which squeezes the slits in the collet shut so it firmly grips the spindle. C-style collets are available in various sizes for a variety of applications.

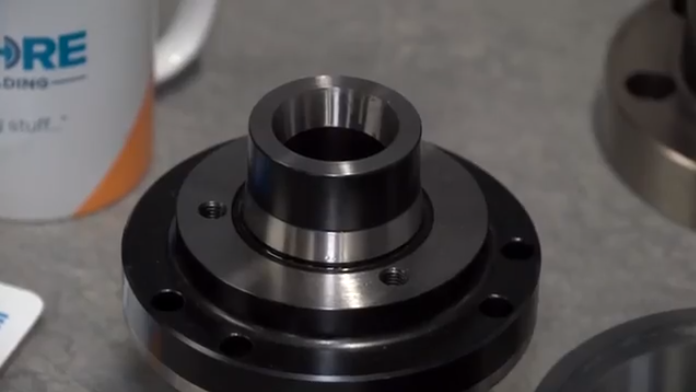

2. Collet blocks

Collet blocks are used to secure the collet before machining. The collet is placed inside the block, and then the block is clamped into the desired position on the machine using a vice. Collet blocks come in different sizes and shapes to allow for various indexing options. Standard collet blocks are usually either square or hexagonal, but custom collet blocks are also available for machining workpieces that require unusual indexing.

3. Expanding collets

Expanding collets are specialised workholding devices for securing workpieces during machining. They use a cylindrical construction with slits that expand to take the tool when force is applied, allowing them to grip the workpiece or tool securely.

HQC (Hardinge’s unique system)

This quick-change collet system from US precision part manufacturer Hardinge is designed for use on automatic screw machines, Hardinge collet-ready CNC lathes, and all other chuck-style CNC lathes with A2-5, A2-6 and A2-8 spindles.

S-style master collets and pads

Designed for multi-spindle automatic screw machines, S-style master collets can also be used on CNC lathes and vertical machining centres. The collet pads allow for quicker changeovers than when using a standard collet and are also easier to store.

Swiss-style collets

Specifically for use with Swiss-style machines, Swiss-style collets are accurate workholding devices ideally suited for precision work.

FlexC Quick Change Collet System

The precisely engineered Hardinge® FlexC Collet Systems mount to A2-5, A2-6, A2-8, and certain flat-back spindle noses.

These systems come in pull-back thru-hole, pull-back dead-length®, and push-to-close dead-length® styles, suitable for single and dual-spindle CNC lathes. With just one spindle mount, you can handle many different part diameters by interchanging vulcanised collet heads between jobs.

When using FlexC, collet changeover takes less than 10 seconds.

Through our trusted partners, we can supply an unrivalled selection of collet workholding options, as well as a variety of chucks, clamps and vices. Contact us today to learn more about our advanced solutions or head over to our online store to browse our workholding range.

What is a collet?

Collets are a type of chuck used to form a collar around an object and to clamp onto the object when tightened firmly. They’re mainly used within the industry to secure cutting tools and workpieces at high speeds and pressures.

Primarily, collets can be divided into two categories; external and internal collets.

- External collets – an external collet is, in essence, a sleeve, usually with a cylindrical internal surface and a conical external surface. External collets are the most commonly used type of collet. They hold the external surface of the tool or workpiece that’s being clamped such as a drill bit shank.

- Internal collets – an internal collet is presented in the form of a truncated cone, which has been drilled and threaded along the centreline. They expand inside the desired objects, securing them in place or holding two separate items, such as telescoping tubes, together. They are most often used to hold workpieces securely from the inside while the surface of the workpiece is machined on the outside.

Advantages and disadvantages of collets

Collets find a wide variety of uses for a host of reasons, but like all workholding options, they have their advantages and disadvantages when compared with the chuck alternatives.

Advantages of collets:

Lightweight – Collets are a modern, lightweight clamping option when compared to chucks. Their light weight allows them to accelerate up to higher speeds than rotary-type chucks. Collets are also less affected by centrifugal force, making them a more accurate and reliable choice for high-speed machining.

Faster set-up time – Additionally, their springy construction and functional design makes collets much quicker and easier to set up than jaw chucks. Their fast-clamping action and quick-release mechanism will save you even more time when changing similarly sized tooling.

Secure workholding – Collets offer a more secure workholding solution than jaw chucks, as there is an almost continuous and equal amount of pressure exerted on the circumference of the shaft by way of the collet nut. This tight concentricity allows for greater accuracy and improved rigidity when in use, reducing runout and helping to prolong tool life. Not to mention this also produces a better finish for your workpiece.

Clamp small diameters – Collets give you the ability to clamp smaller diameters than chucks. They excel at clamping parts with extremely small diameters, allowing for versatile workholding options across a wide range of applications. Custom collets can be used for off-centre turning or holding irregular-shaped parts.

Some more benefits include:

- Less affected by centrifugal force

- Tight concentricity

Disadvantages of collets

Collets are limited in the range of workpiece sizes they can accommodate and are ideally suited for repetitive jobs where the clamping requirements don’t vary greatly. They are also better suited for clamping tooling with longer shanks and workpieces with consistent diameters.

Where are collets used?

While metalworking utilises the broadest range of collet varieties, collets are used in a surprising number of applications:

Woodworking

In woodworking, collets are used in various handheld and machine-operated rotating tools, from drill presses to routers. Furthermore, collets are also used to secure larger woodworking pieces during machining. Collets are favoured in woodworking applications as they are hardwearing and ideal for performing repetitive tasks.

Metalworking

Collets have a variety of applications in the metalworking industry. Their ability to secure small-diameter precision parts operating at very high speeds makes them especially suited to this type of work. Equally, their fast setup and release times make them ideal for use with multiple tools of a similar size.

Craft hobbies

Collets aren’t just used in industrial workholding. Hobbyist, artists, and craftspeople use tiny collets to secure interchangeable parts within handheld tools such as craft knives, drills, and files.

Watchmaking

Another use for tiny collets is in watchmaking, where watchmakers use collets that are sized in 0.1mm increments to secure the delicate workpieces to their lathes.

Combustion engines

Collets are used within combustion engines to regulate engine valves. Also known as valve locks, keepers, or clips, the collet attaches to the valve through the spring retainer and sits between the valve spring and the valve.

Semiconductors

Collets are used in the semiconductor industry to pick up a die from a wafer after a die-cutting process.